Prime water BV, based in Lommel, Belgium, has been part of the Aqua free Group since 2016 and complements our product and service portfolio. With the change of the company name, we want to integrate Prime water's range of capabilities more closely into the group.

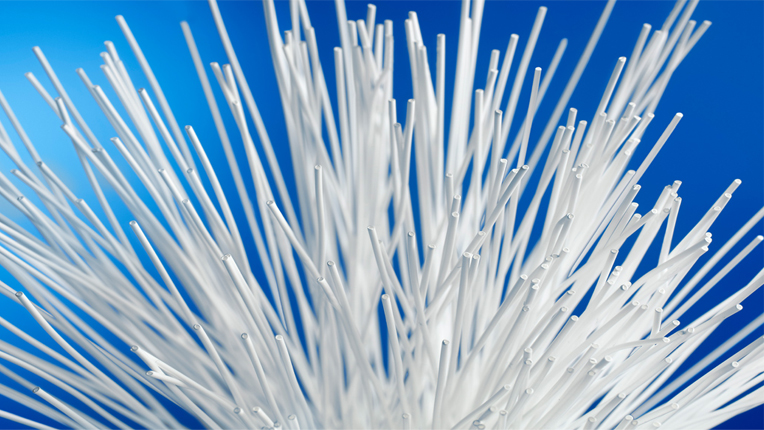

Aqua free Industries BV (after the change of name) works for you in the same way as before. In our specialized portfolio, we offer high quality hollow fiber membranes for Microfiltration and Ultrafiltration, the development and production of customized hollow fiber membrane cartridges for disinfection of drinking water as well as our standard filter portfolio.